Initially on the phone, in mid June, the Jeep workshop at Srinagar gave a long list of parts that would be replaced – almost amounting to some Rs 12 lakhs.

BHPian Rajain recently shared this with other enthusiasts.

So, here is the full lowdown on what happened with the Meridian in Leh. The reason for the delay was actually lack of information and a huge diversity of views (read excuses) coming in from Jeep management and workshop in Srinagar.

Back in early June many family members (my brother’s entire family) had gone to Leh from Gurgaon. They were in 2 Jeep vehicles – Compass and Meridian. The Compass has been to Kargil a couple of times before and Padum besides other trips including to Nepal. It has been reliable and sturdy. It is a BS 4. The Meridian was added to the garage as a replacement of Endeavor (2.2). The Endeavor had done multiple duties all over the country with trips in Gujarat to Nepal to J&K. This was the first major trip for the Meridian which has done less than 10k. It is a BS 6.

Anyway, back to the Leh trip. The initial few days remained uneventful. Zoji La was crossed, Padum and back to Kargil, then Leh, Nubra and Turtuk. Back to Leh and then Pangong Tso and Chumthang. It was somewhere around Tangtse the two vehicles were navigating a dirt track when this happened. The vehicle in front was Jeep Compass being driven by my elder brother (multiple trips to Leh, many thousands of kms in Ladakh, posting in Siachen, Thoise and even a cycling trip from Manali to Khardung La), behind the Compass was the Meridian (being driven by my nephew – also multiple trips to Leh, camping in Kargil, cycling from Manali to Khardung La). [the background just to establish that this was not the first rodeo for the two at the wheel].

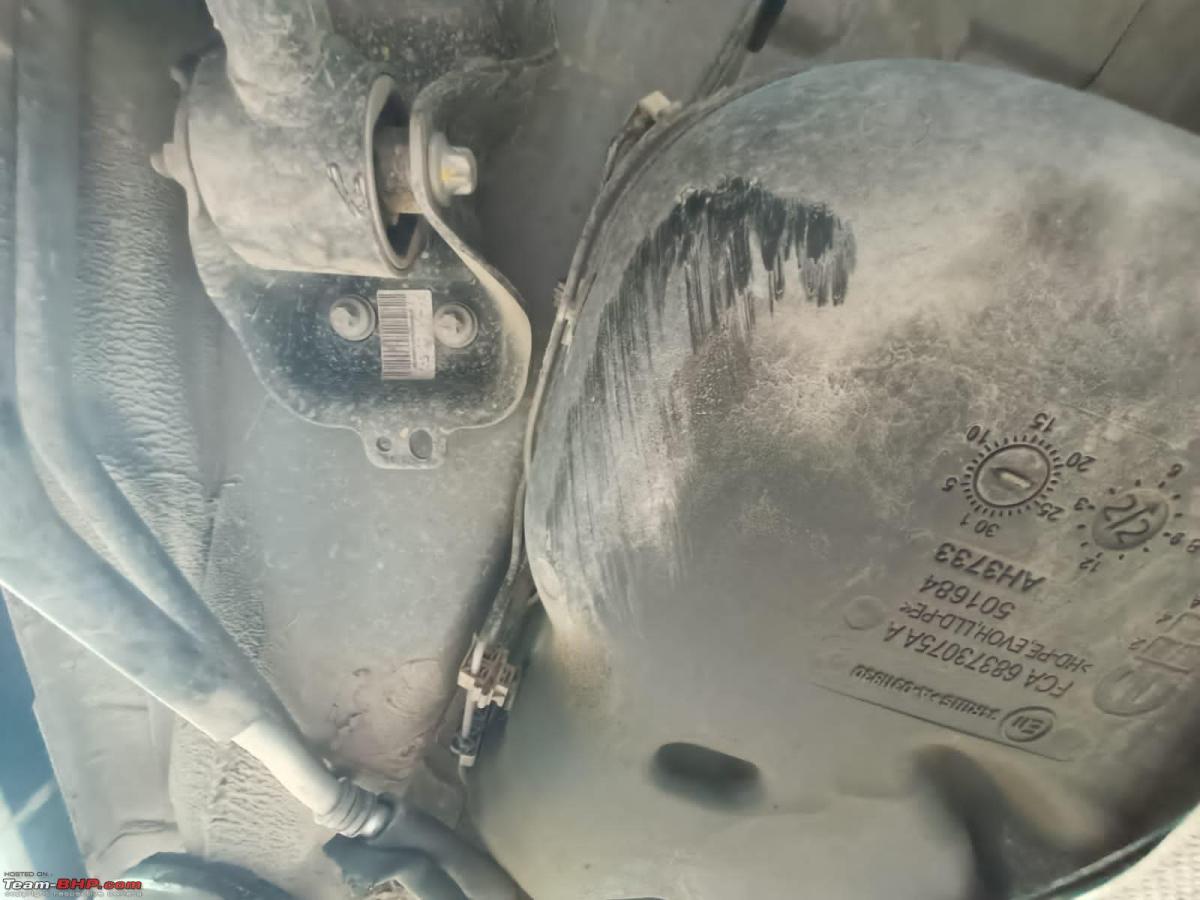

The vehicles were at speed of around 25-30 kmph. Dirt track meant many small stones. The Compass went smoothly over a few, no problem and right behind, about 8-10 meters was the Meridian . The Meridian felt more jerks and sounds as if stones had scraped the underbelly or gone through the left side wheel arch. The Compass had gone over the same dirt tracks and there was no issue at all. So, naturally there were no big stones. They signalled and both vehicles stopped. A physical inspection did not reveal anything. There were no leaking pipes either. The vehicles drove for a few meters and stopped again to see any signs of anything leaking – again nothing was leaking. They began the journey but within 2-3 kms warning lights came up (I am informed 3-4 of them – which all, I don’t have the detail right now). They stopped the vehicles again. A couple of restarts and back and forth did not yield anything. A fairly thorough physical check undercarriage revealed many scratches as one sees in an underbelly. The DPF light had also come up. So, some physical damage going over stones (over which the Compass went through smooth and easy – just 8-10 meters ahead). After a while, when they could get the mobile connection and spoke with Jeep support they were informed, leave the vehicle there and it will need to be brought down in a flat bed truck. A nearby army unit sent in a couple of vehicles, bags transferred and the remaining journey continued.

The flat bed truck came in from Srinagar and picked up the Meridian in about 25-30 hrs and in about 4-5 days the vehicle was at the Srinagar workshop. The remaining journey was completed with Compass and a cab. The family flew out of Srinagar and the Jeep stayed there for repairs.

Now, here the ordeal began. Initially on the phone, in mid June, the Jeep workshop at Srinagar gave a long list of parts that would be replaced – almost amounting to some Rs 12 lakhs (yes twelve lakhs). Naturally the insurance company was notified. Repeated follow ups, lack of comms, no transparency meant it was a struggle to fully understand what exactly broke down and what would be fixed. They did send multiple photos so it did appear underbody many parts would be replaced. The list they gave was

1. Rear Cross Member.

2. Left Side Rear Bracket.

3. Left Side Rear Sheild.

4. Left Side Rear Clipper.

5. Left Side Rear Alloy.

6. Silencer.

7. Left Side Rear Desk Router.

8. Left Side Rear Knuckle.

9. Left Side Rear Shocker.

10. Left Side Rear Brake Shoes.

11. Left Side Rear Support Arm.

12. Left Side Rear Fender Lining.

13. Left Side Rear Shocker Bracket.

14. Fuel Tank.

15. Sensor.

16. Silencer Brackets Both.

17. Left Side Rear All Arms.

18. Left Side Front Arm.

19. Link Road.

20. Stabilizer Bar.

21. Bumper Lip.

22. Splash Guard.

23. Cross Member.

24. All AC Pipes.

About 2 weeks later (early July the Jeep Srinagar workshop informed the insurance is taking time. Another week later, still taking time. Then after the insurance guy saw it all, he deducted many parts and approved just some of them. By now the cost had dropped to Rs 4 lakhs or so. Another week passed. By end July Jeep Srinagar workshop confirmed that parts are not there and have been requisitioned. The parts arrived 2 weeks later and then they informed these were not the parts and there was some mix up. We are certain the goof up was incorrect part numbers were ordered and incorrect parts arrived at the workshop. These parts then had to be returned to where ever they came from and new set of parts were requisitioned. Another 2-3 weeks go by. Parts are yet to arrive. Some time in end of Aug the parts arrived. The Jeep Srinagar workshop takes 2 days and fixes them all up and reports in early Sept that the vehicle is ready. And a few days ago, my brother went to Srinagar and drove the Meridian back to Gurgaon. The eventual bill that came from all of the 10 weeks in the workshop was Rs 1,10,000 (abouts) that the insurance company paid the entire 100%.

So, overall some impressions –

1. Apparently the Meridian has a small hard plastic underbody protection plate and it is plain insufficient to protect anything. Imagine if the Compass went over the same stones (fairly small so much that the under carriage was not hit) and the Meridian scraped the underbody, ripped the underbody and many parts were damaged, makes one wonder how and why. To think of it the size of the stones was small – small enough that a Compass passed over them with no issues. The speeds were between 25-30 kmph.

2. The Jeep Srinagar workshop could not get its act together. The good part was the flat bed truck came and picked up from Tangtse in under 2.5 days and it was with Jeep Srinagar workshop in under 5 days. But the workshop itself kept giving stories after stories – imagine if their initial estimate was Rs 12 lakhs then after the insurance company person did the survey and said Rs 4 lakhs and the final bill after 10 weeks was Rs 1.1 Lakh. Awesome. Their stories ranged from x part is not available and y part is not available. X was ordered and Y has arrived and will be sent back. Blah blah blah.

3. The good news is Meridian is back doing its daily duties. It was checked again in Gurgaon workshops and they attested that the job was well done. The good news is also that insurance paid for it entirely (full 100%)

4. Overall, one think how come the build quality was so bad (or the GC differing by a few millimetres) that the vehicle packed up so quickly in the middle of rather remote areas. And then the Jeep Srinagar workshop kept giving some excuse and some story.

5. The support from Jeep is minimal, escalations don’t help and parts are hard to come by. In this day and age no vehicle should be parked at a workshop for almost 3 months with no transparent comms. In a drive like that with 3 generations of people travelling in Jeep vehicles would have made a good story on reliability and toughness. Sadly, that was not to be. The conversations at my brothers home these days are around moving away from the Jeep brand.

My apologies, it took long for me also to understand what all parts broke down and how Jeep responded.

Cheers

Rajain

Read BHPian comments for more insights and information.

Source: Read Full Article